Air filtration

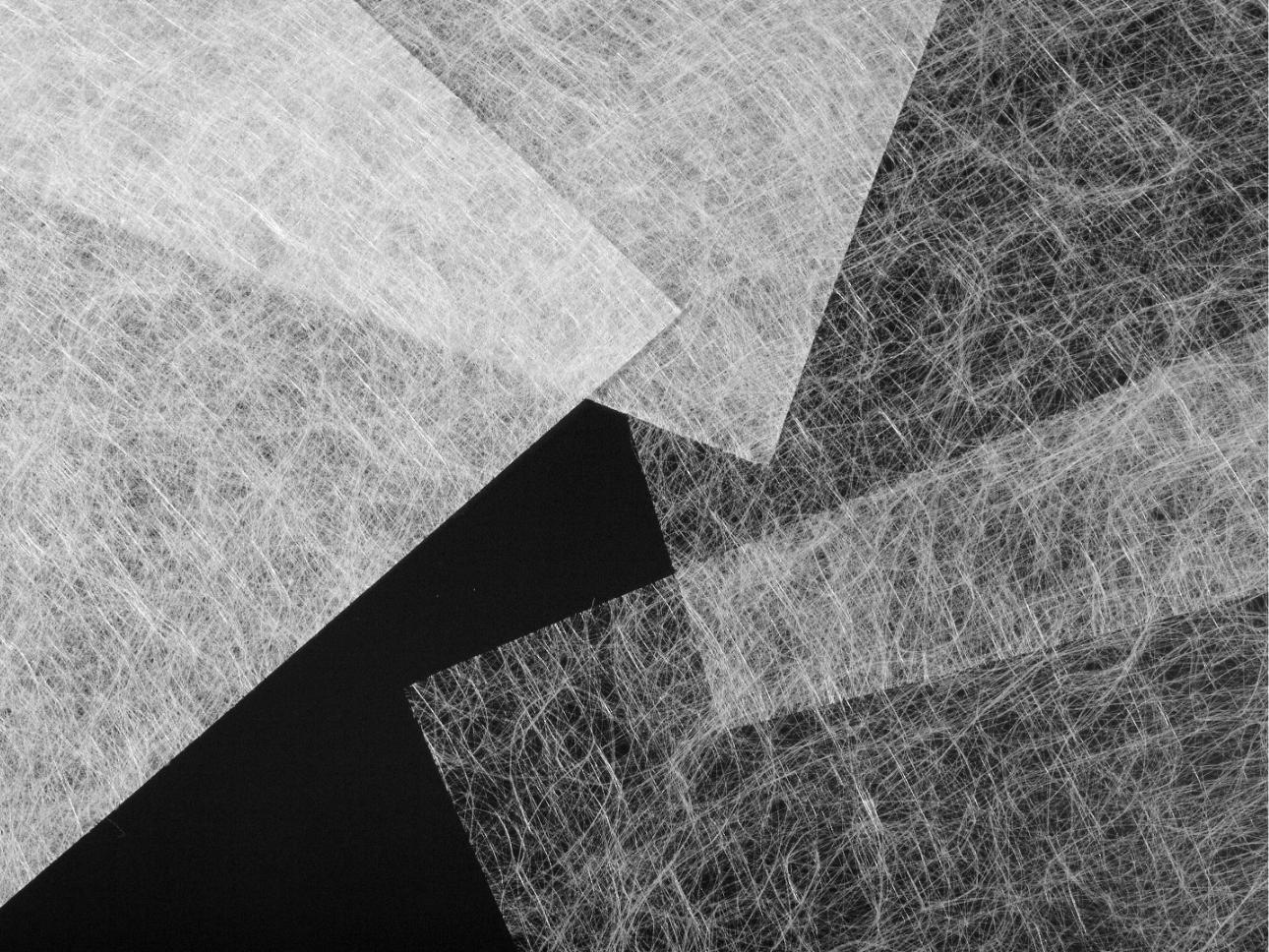

The Filtura® portfolio offers superior filter media, side bands, carrier materials and activated carbon solutions for the air filtration industry

The Filtura® experts use advanced technologies such as spunbond, wetlaid, carded, meltblown or 3D-matting methods to create advanced filter media. By integrating and combining these diverse techniques, we can tailor excellent filter solutions to meet the specific demands of various industries, ensuring optimal performance, durability, and filtration efficiency. This approach allows us to create products that deliver superior air, liquid and automotive filtration.

✓ Broad possibilities under one roof

✓ Extensive standard product portfolio

✓ Additional functionalities possible

Our multi-layer filter media meet a wide range of filtration requirements. For removing odors and emissions, we design filter media with a high-performance activated carbon layer, e.g. for cabin air filtration. Or we offer composite solutions for HVAC applications (e.g. spunbond + meltblown nonwovens or enhanced needle-punched nonwoven layers). These are just a few examples that illustrate the diversity of our composite filter media.

Applications

✓ Air filtration: e.g. HVAC

✓ Liquid filtration: e.g. food & beverage

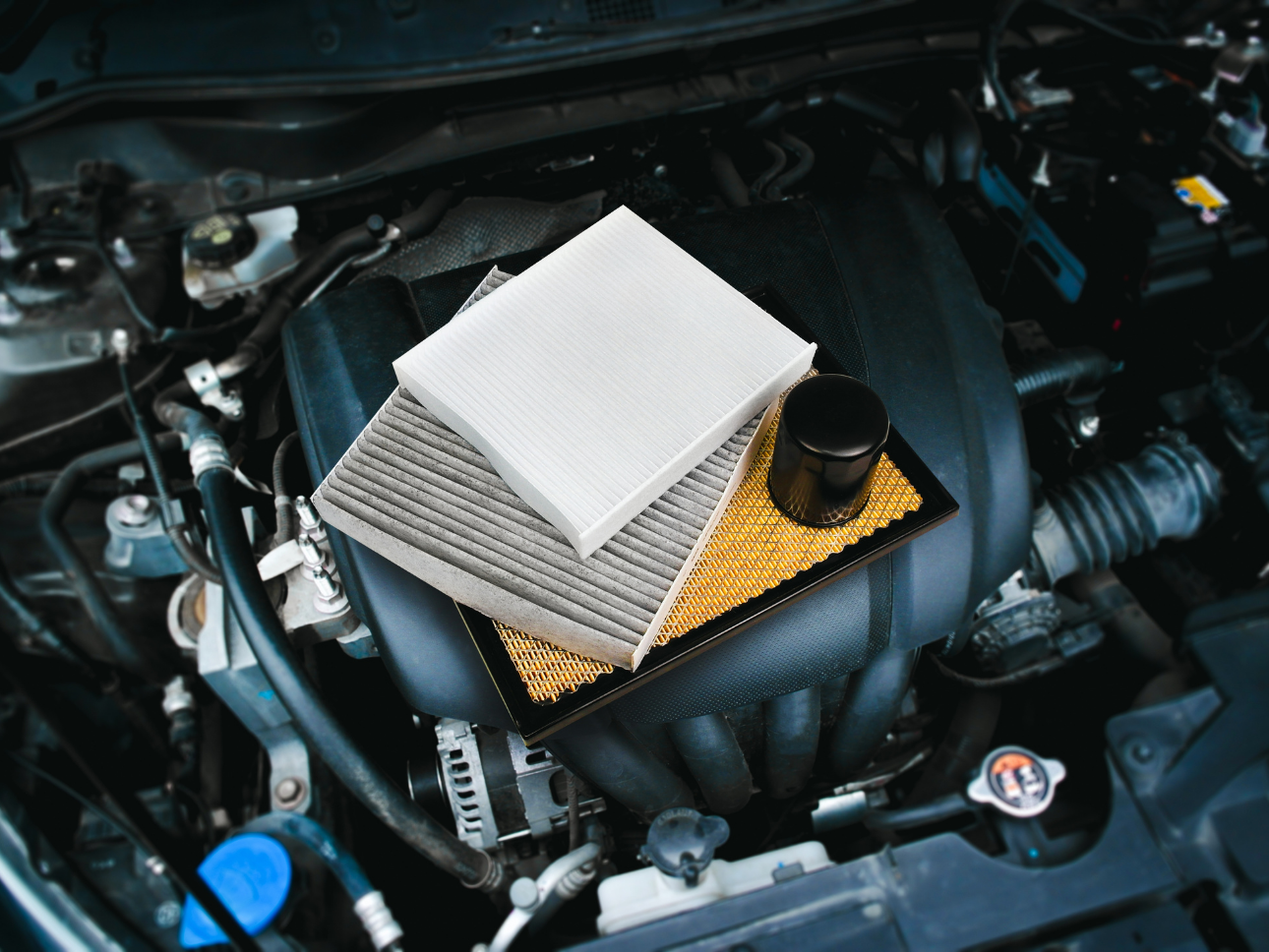

✓ Automotive filtration: e.g. cabin air

Decades of experience, pioneering technologies, a continuous development process, and professional support: Filtura® offers filter manufacturers all of this under one roof. These advantages are particularly important when developing customized solutions.

We work closely with our customers to develop the composite they need - from sophisticated HVAC solutions to activated carbon filter media with additional functionalities, including antiviral properties. By using different layer combinations and/or incorporating functional layers, we achieve the desired filtration performance, breathability, and mechanical strength.

Decades of experience, pioneering technologies, a continuous development process, and professional support: Filtura® offers filter manufacturers all of this under one roof. These advantages are particularly important when developing customized solutions.

We work closely with our customers to develop the composite they need - from sophisticated HVAC solutions to activated carbon filter media with additional functionalities, including antiviral properties. By using different layer combinations and/or incorporating functional layers, we achieve the desired filtration performance, breathability, and mechanical strength.

Our team of experts are here to help you.

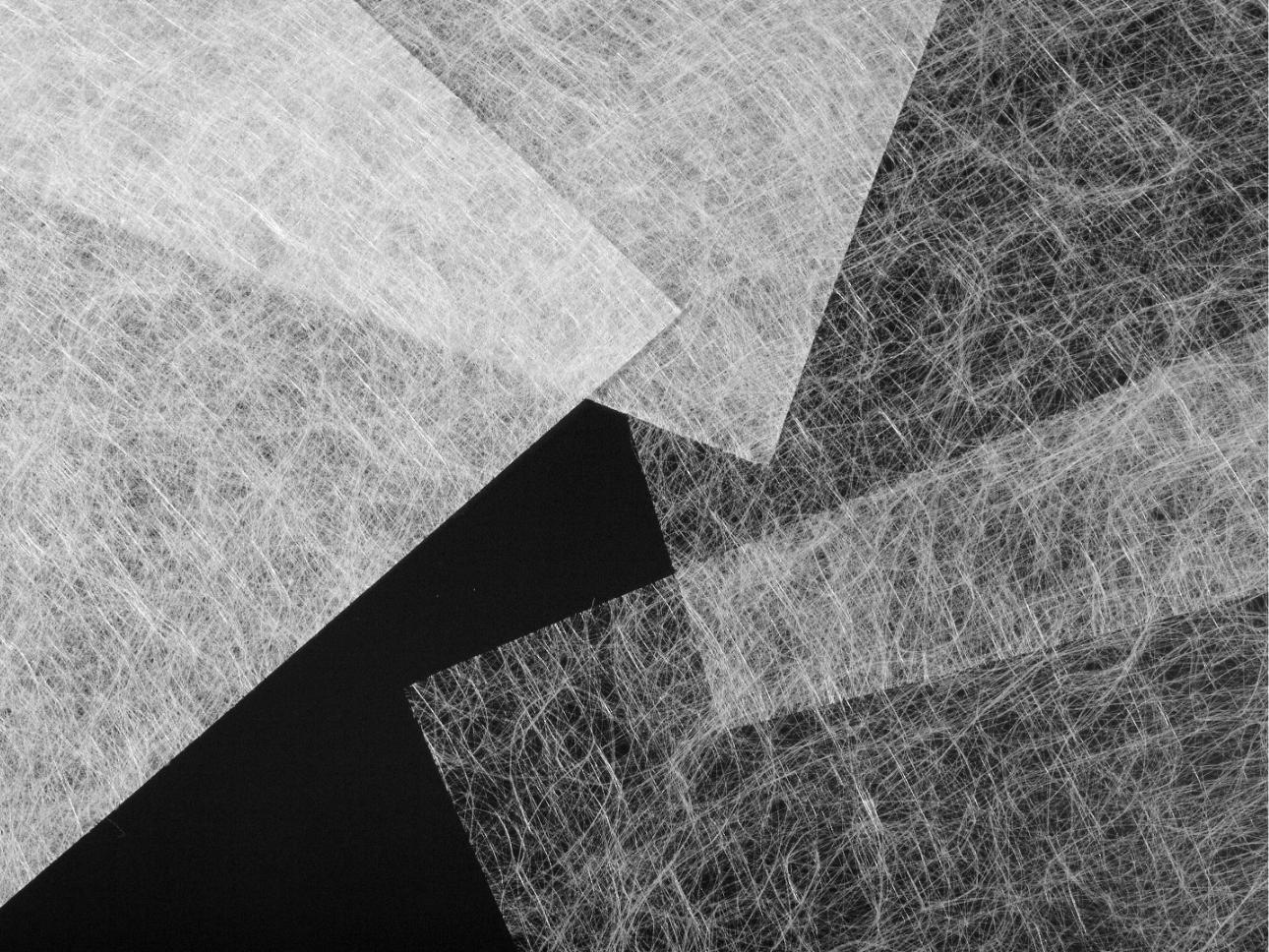

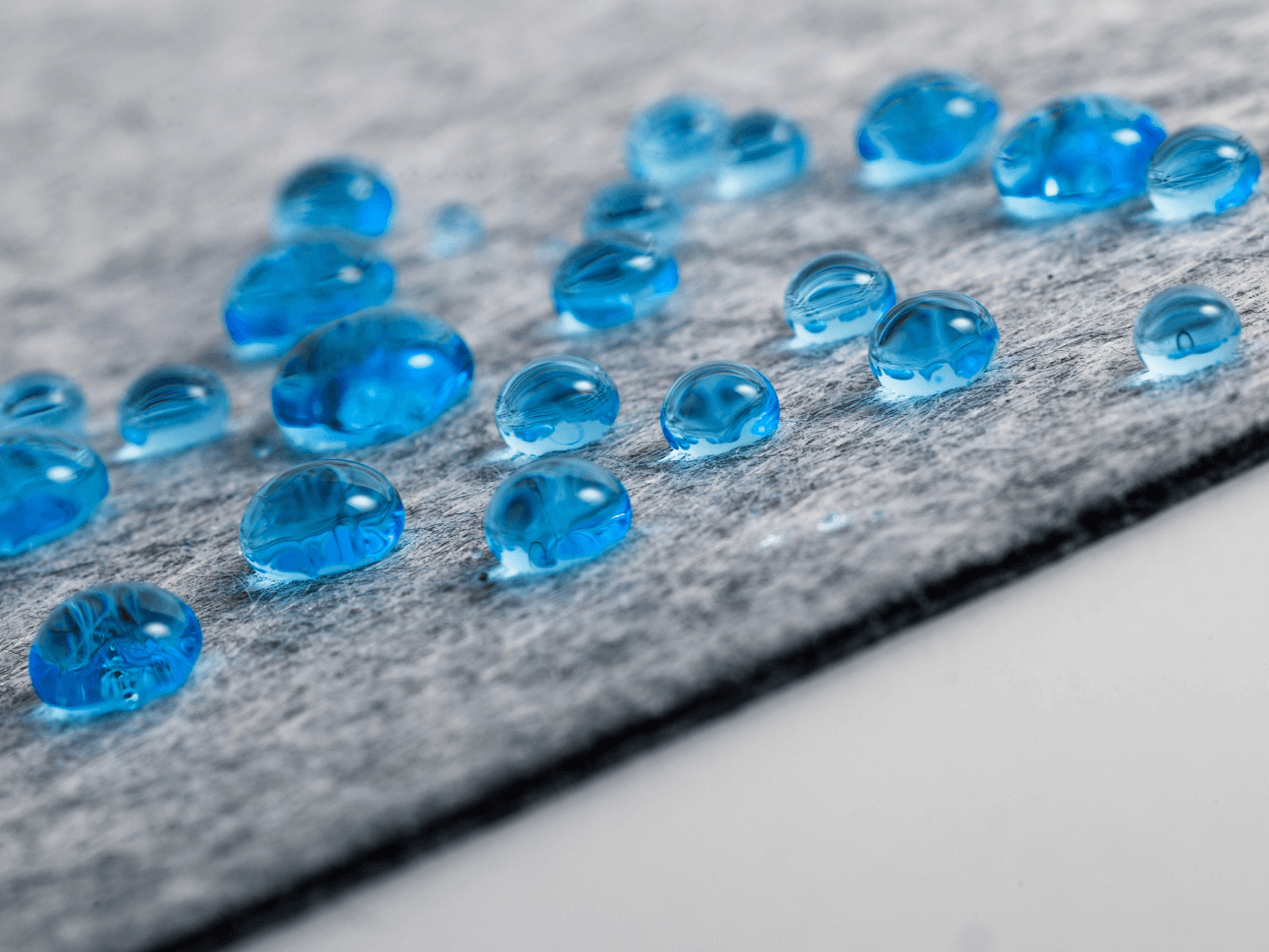

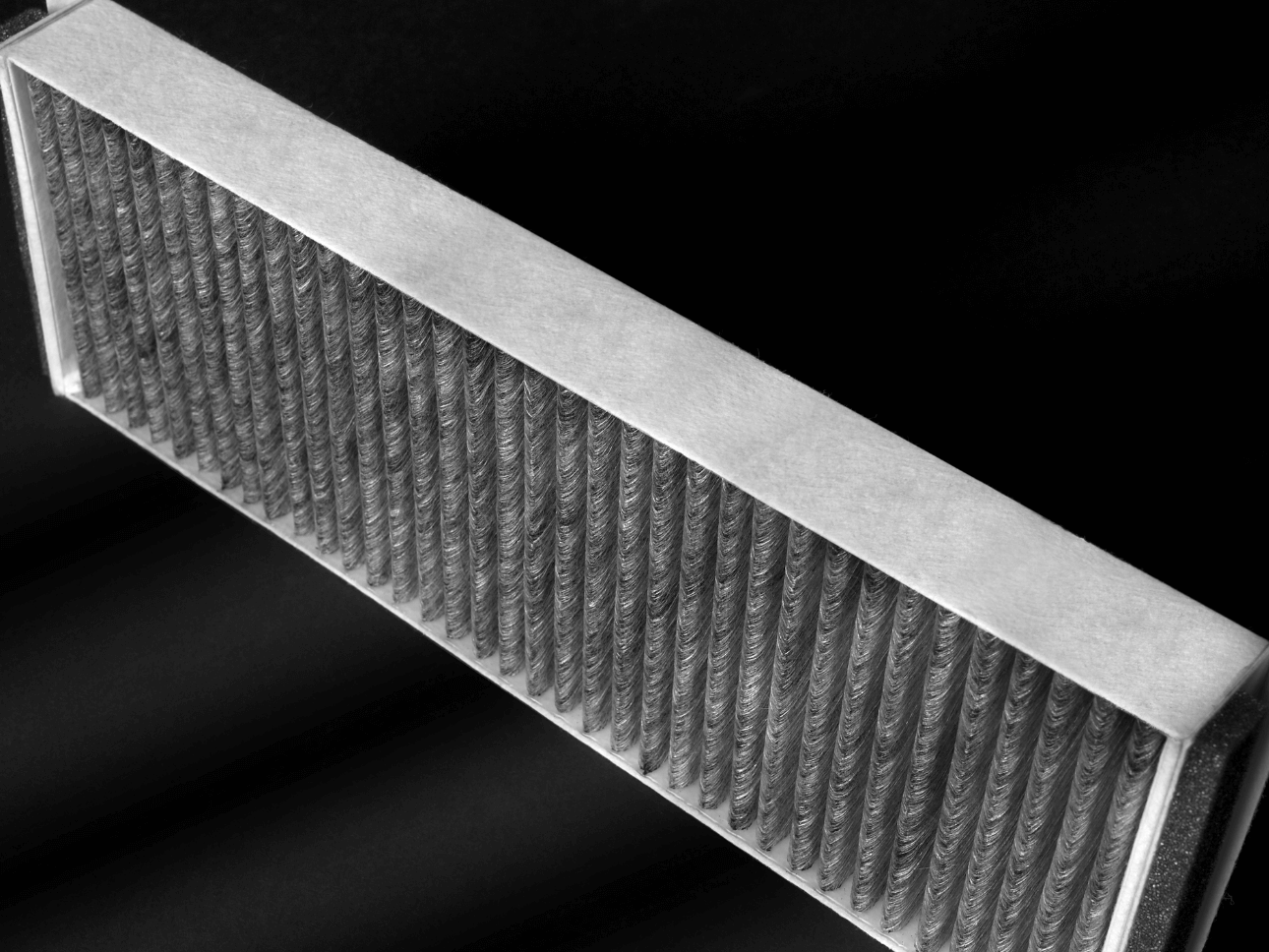

Filtura® spunbond nonwovens combine premium filtration efficiency with excellent durability. The fabrics can be tailored to meet the individual requirements of filter manufacturers. All product variants feature high stiffness and outstanding dimensional stability for sharp, stable pleats even under the harshest conditions.

Applications

✓ Air filtration: e.g. HVAC

✓ Liquid filtration: e.g. coolants & lubricants, pool & spa

✓ Automotive filtration: e.g. cabin air

Filtura® spunbond nonwovens provide a high degree of uniformity in terms of thickness, porosity, and surface properties. Thanks to their design, the fabrics are not only easy to laminate with membranes and other filtration layers, they also show no fraying during processing and throughout the lifetime of the finished filter element.

Filtura® spunbond nonwovens feature high longitudinal and transverse strength and rigidity. They therefore reliably remove impurities and help to create high, sharp, and stable pleats for maximum performance. The portfolio includes spunbond nonwovens with high permeability which helps to achieve low pressure drop, supporting cost-effective operation of the filter.

The Filtura® portfolio comprises spunbond nonwovens made from FDA-approved raw materials. With NSF certification, these fabrics are suitable for manufacturing water filter equipment.

Filtura® spunbond nonwovens can be customized to meet individual requirements. Typical modifiable factors include the polymers used (PP, PES, PE or PA), fabric weight per unit area, antibacterial properties, thickness, and permeability. Microfilament fabrics are also available.

Thanks to their excellent thermal resistance, tear strength and resistance to chlorine, bromine and other substances, Filtura® spunbond nonwovens maintain their properties even under the harshest conditions. Pleats created with these fabrics withstand high pressure and frequent cleaning.

Filtura® spunbond nonwovens provide a high degree of uniformity in terms of thickness, porosity, and surface properties. Thanks to their design, the fabrics are not only easy to laminate with membranes and other filtration layers, they also show no fraying during processing and throughout the lifetime of the finished filter element.

Filtura® spunbond nonwovens feature high longitudinal and transverse strength and rigidity. They therefore reliably remove impurities and help to create high, sharp, and stable pleats for maximum performance. The portfolio includes spunbond nonwovens with high permeability which helps to achieve low pressure drop, supporting cost-effective operation of the filter.

The Filtura® portfolio comprises spunbond nonwovens made from FDA-approved raw materials. With NSF certification, these fabrics are suitable for manufacturing water filter equipment.

Filtura® spunbond nonwovens can be customized to meet individual requirements. Typical modifiable factors include the polymers used (PP, PES, PE or PA), fabric weight per unit area, antibacterial properties, thickness, and permeability. Microfilament fabrics are also available.

Thanks to their excellent thermal resistance, tear strength and resistance to chlorine, bromine and other substances, Filtura® spunbond nonwovens maintain their properties even under the harshest conditions. Pleats created with these fabrics withstand high pressure and frequent cleaning.

Reach out to one of our experts.

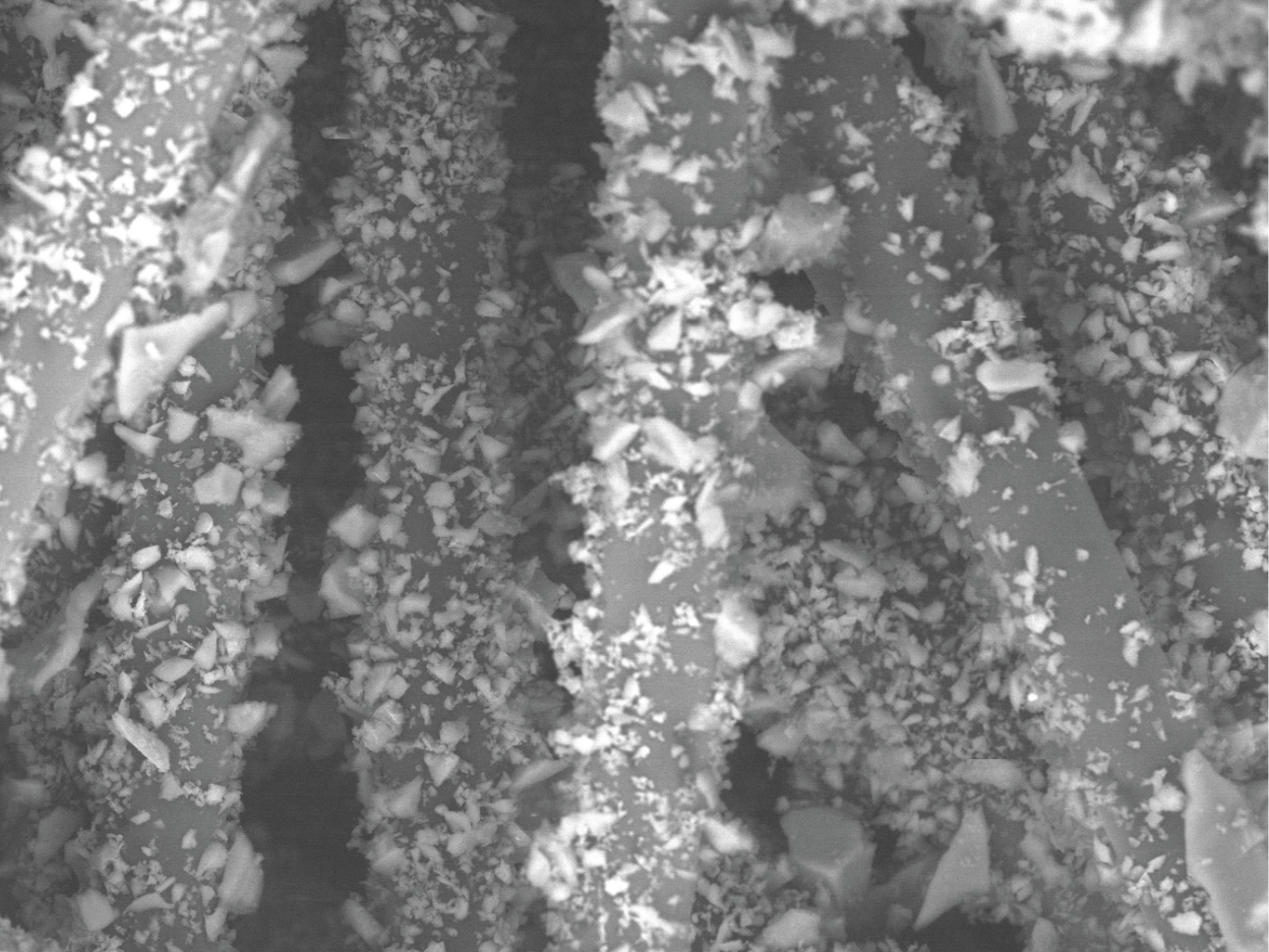

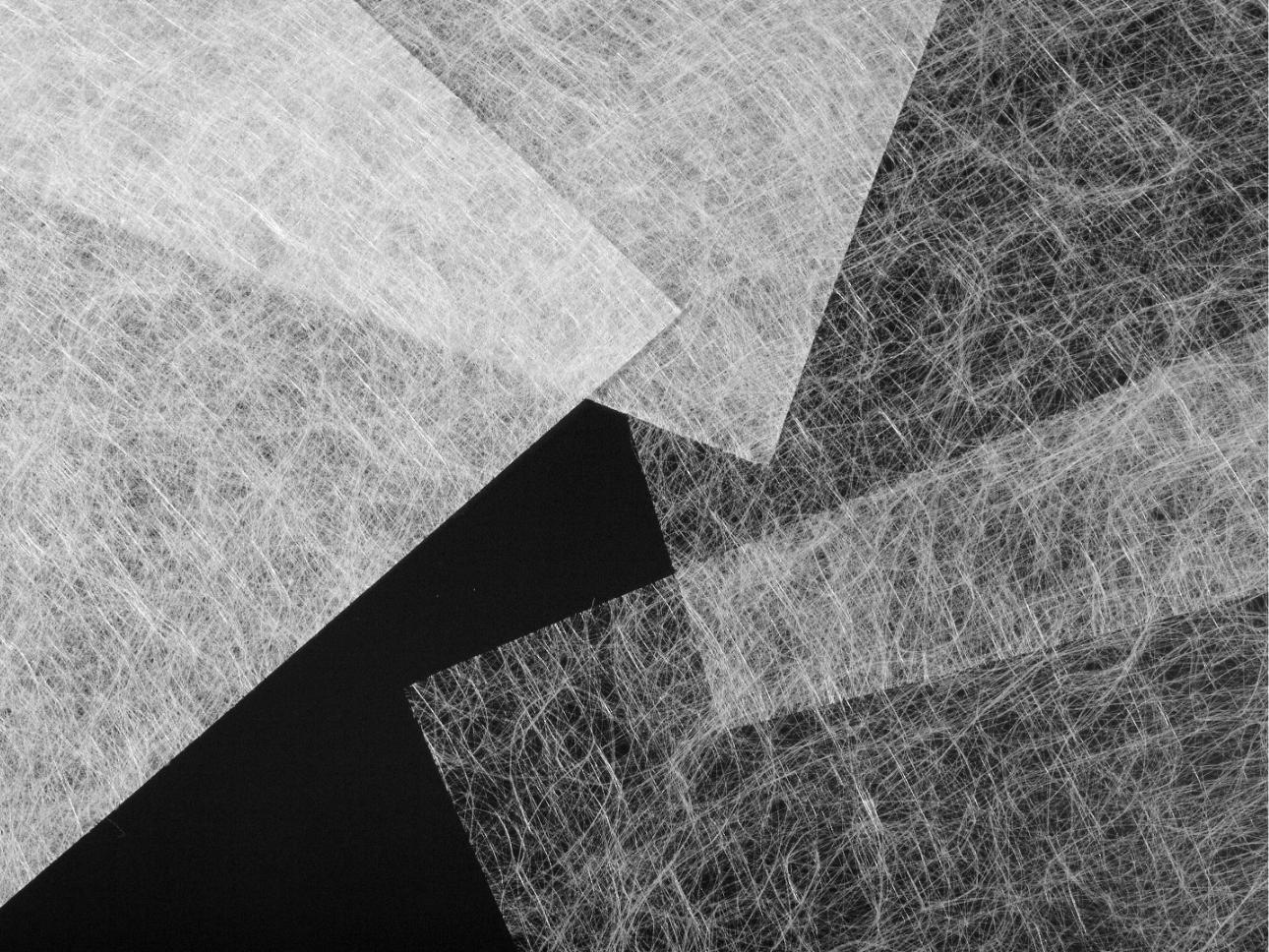

The Filtura® portfolio comprises a wide range of carded nonwovens consolidated through thermal (thermobond), chemical (chembond), or mechanical bonding (needlepunch). The production process allows for the incorporation of different synthetic fibers according to specifications. Filtura® carded nonwovens can be processed as a single layer or integrated into multi-layer solutions, such as needle-punched nonwovens with activated carbon, ideal for targeted gas adsorption.

✓ Air filtration: e.g. HVAC

✓ Liquid filtration: e.g. milk filtration

✓ Automotive filtration: e.g. cabin air, engine air intake

Filtura® carded nonwovens can be customized to meet specific performance requirements by using various fiber combinations and distributions as well as finishing treatments. This flexibility allows characteristics such as strength, adsorbent behavior, and elasticity to be tailored as needed.

Filtura® carded media maximize dirt-holding capacity and flow rates. These features contribute to higher air quality and reduce the need for frequent filter changes.

Filtura® carded nonwovens can be customized to meet specific performance requirements by using various fiber combinations and distributions as well as finishing treatments. This flexibility allows characteristics such as strength, adsorbent behavior, and elasticity to be tailored as needed.

Filtura® carded media maximize dirt-holding capacity and flow rates. These features contribute to higher air quality and reduce the need for frequent filter changes.

Our team of experts are here to help you.

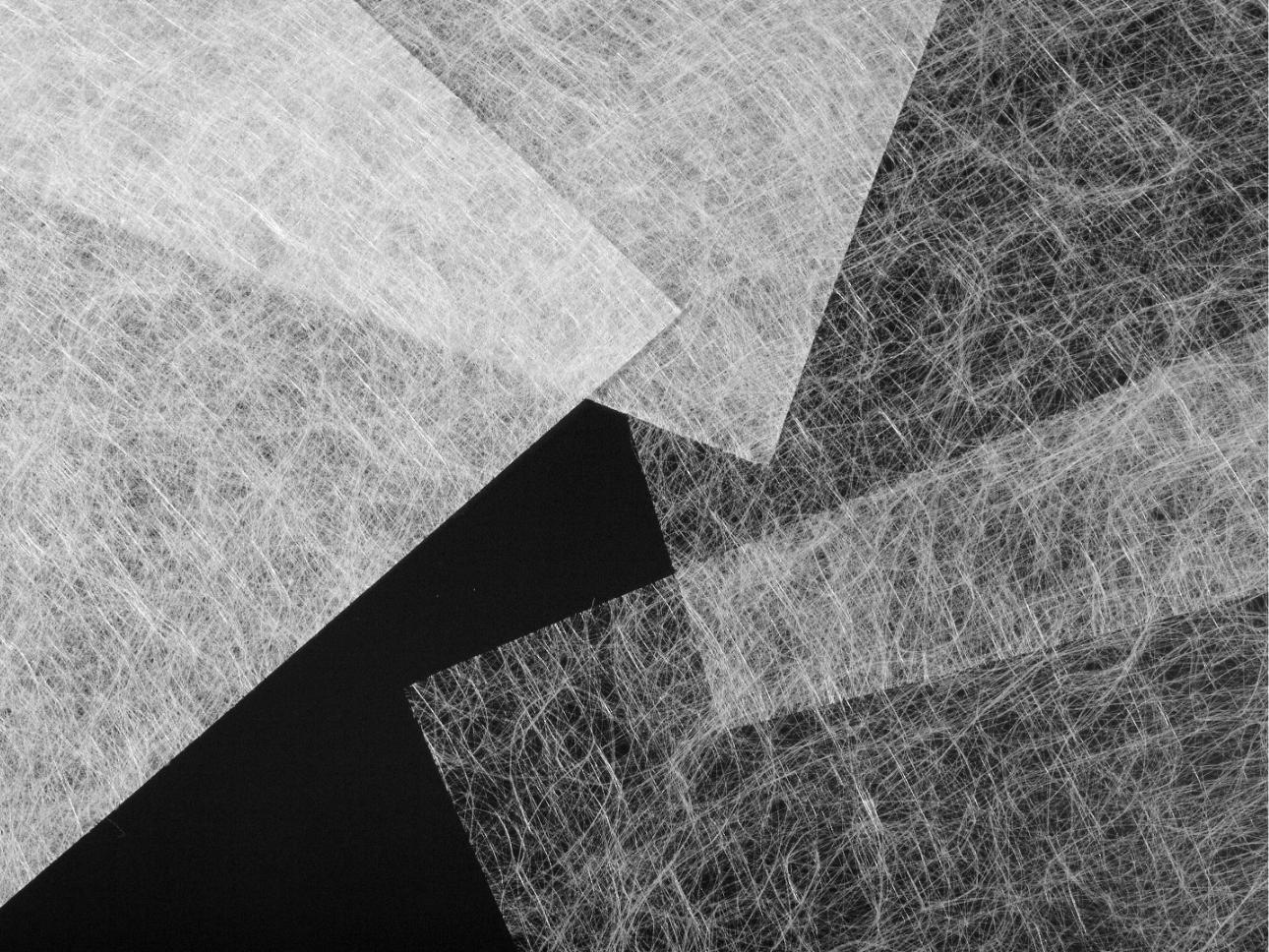

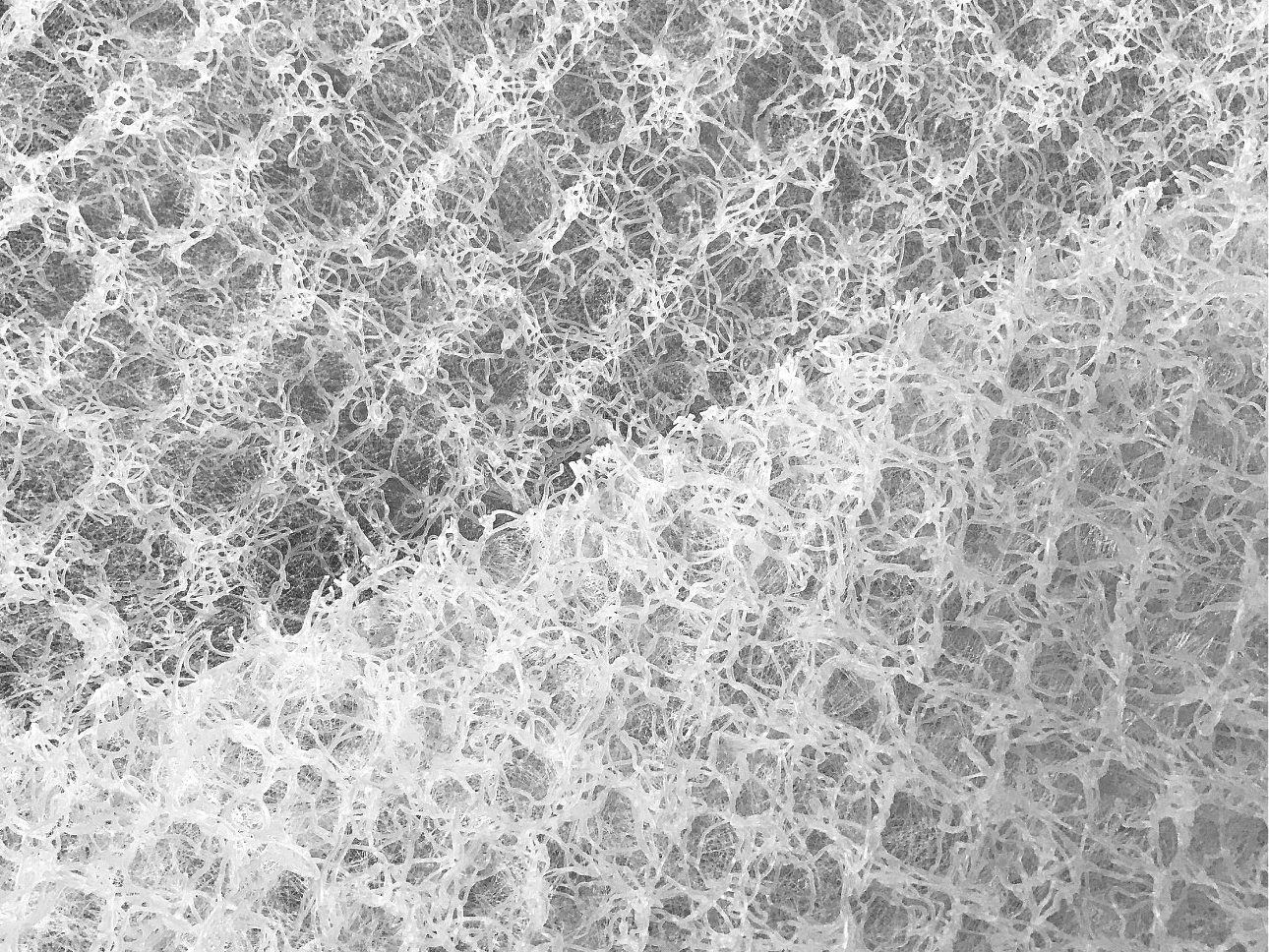

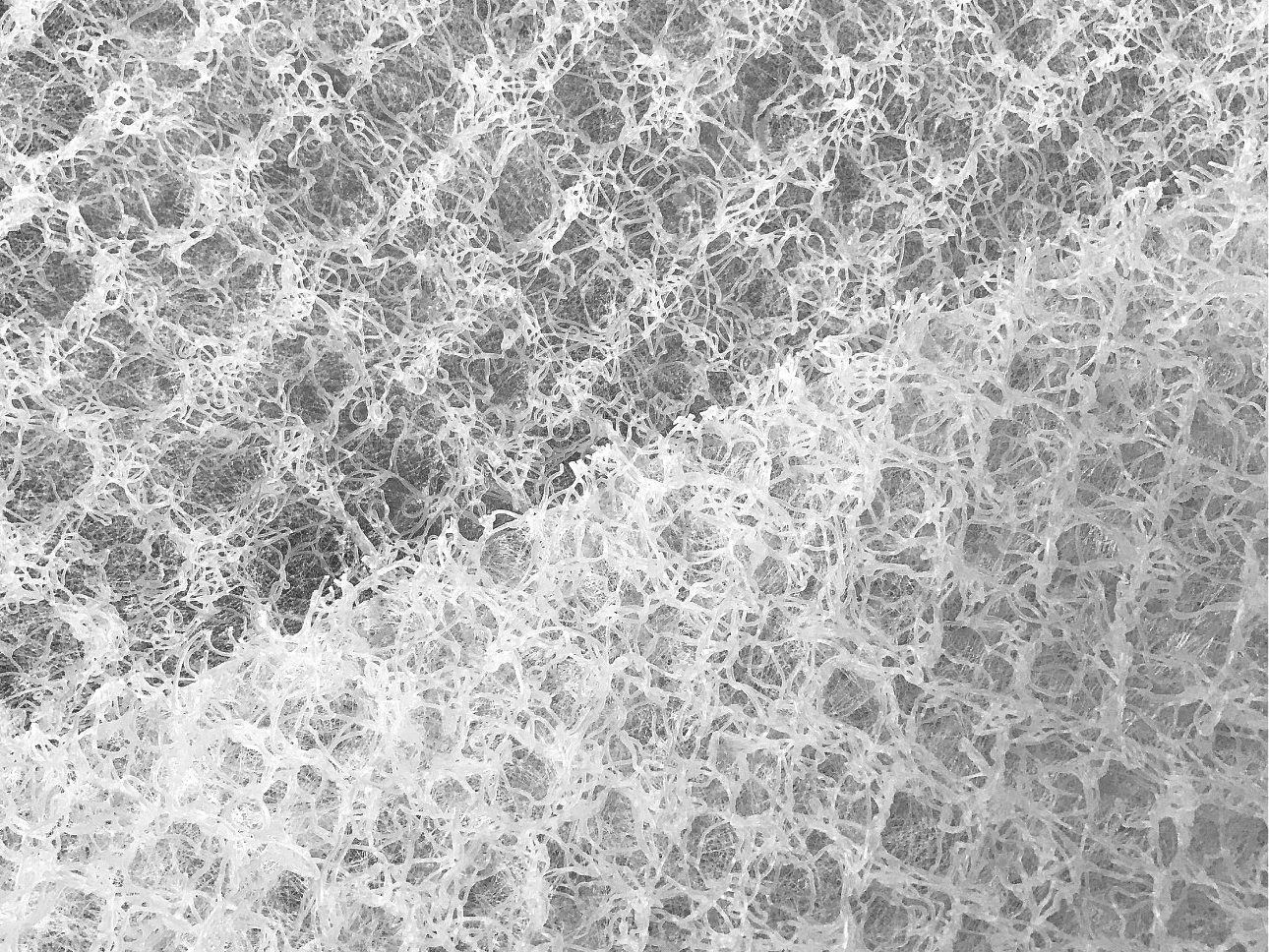

Filtura® meltblown nonwovens are as diverse as our customers and their requirements. The right fabric can be designed for every filter configuration by using a wide range of different polymers and additives. Additionally, various grades of air permeability and filter efficiency, including ePM1 up to 80%, are available. The Filtura® portfolio comprises single-layer meltblown fabrics as well as composite filter media, e.g. a spunbond nonwoven carrier material laminated to a meltblown nonwoven filtration layer.

Applications

✓ Air filtration: e.g. HVAC

✓ Liquid filtration: e.g. food & beverage, oil filtration

✓ Automotive filtration: e.g. cabin air

The filtration efficiency of Filtura® meltblown nonwovens can be tailored to individual customer specifications. The fabrics are characterized by a wide air permeability range which allows a variety of different applications. In terms of materials, the nonwoven filter media can be made of different polymers (PET, PP, PE, PA, PBT and PBS) and can be combined with layers of our drylaid and spunbond nonwovens.

Additives can be integrated into the masterbatch polymers, including hydrophilic, colored, flame retardant, UV stabilization, and electrostatic charging agents. This avoids extra costs during the downstream manufacturing process.

The filtration efficiency of Filtura® meltblown nonwovens can be tailored to individual customer specifications. The fabrics are characterized by a wide air permeability range which allows a variety of different applications. In terms of materials, the nonwoven filter media can be made of different polymers (PET, PP, PE, PA, PBT and PBS) and can be combined with layers of our drylaid and spunbond nonwovens.

Additives can be integrated into the masterbatch polymers, including hydrophilic, colored, flame retardant, UV stabilization, and electrostatic charging agents. This avoids extra costs during the downstream manufacturing process.

Get in touch with our team.

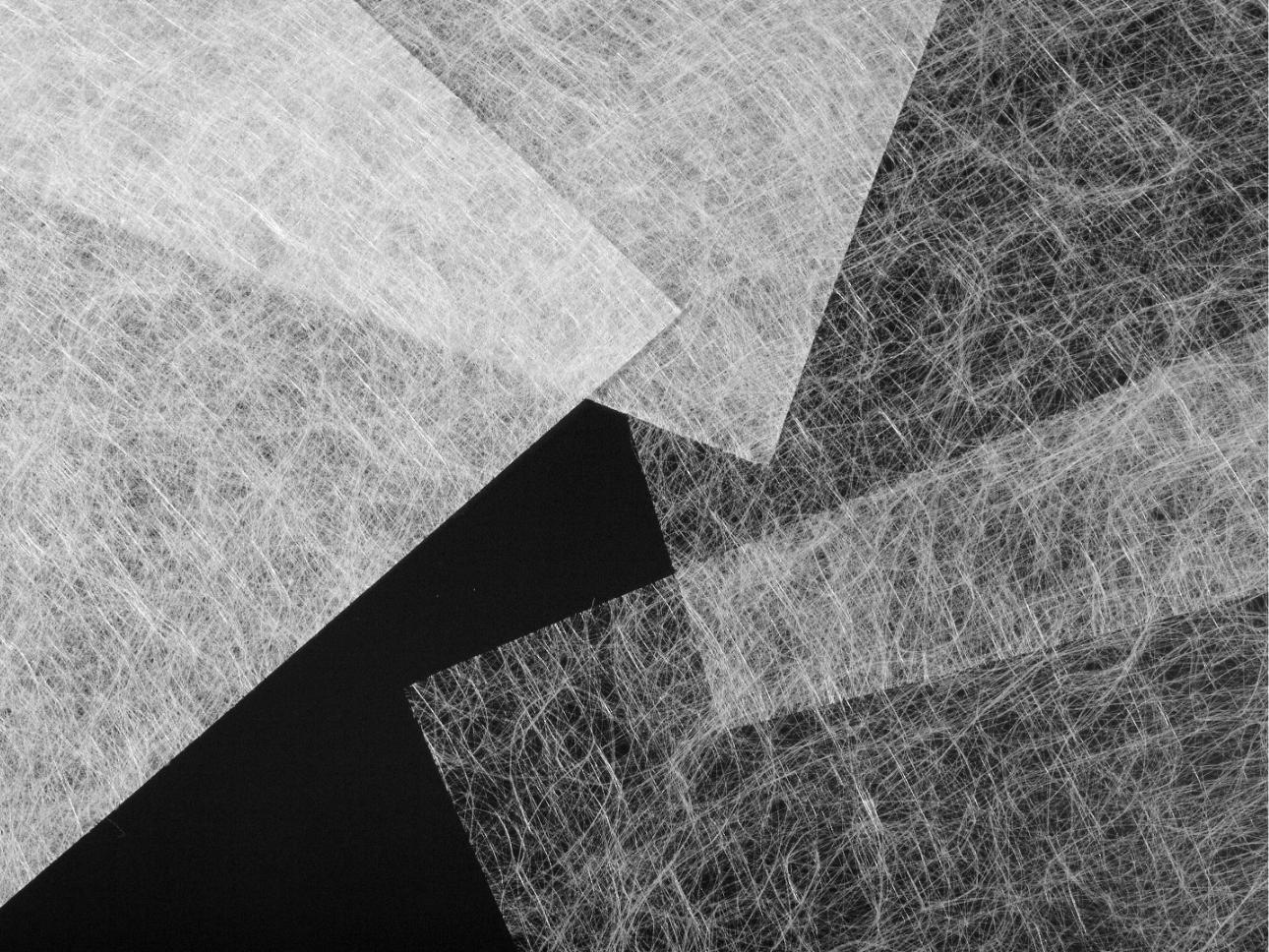

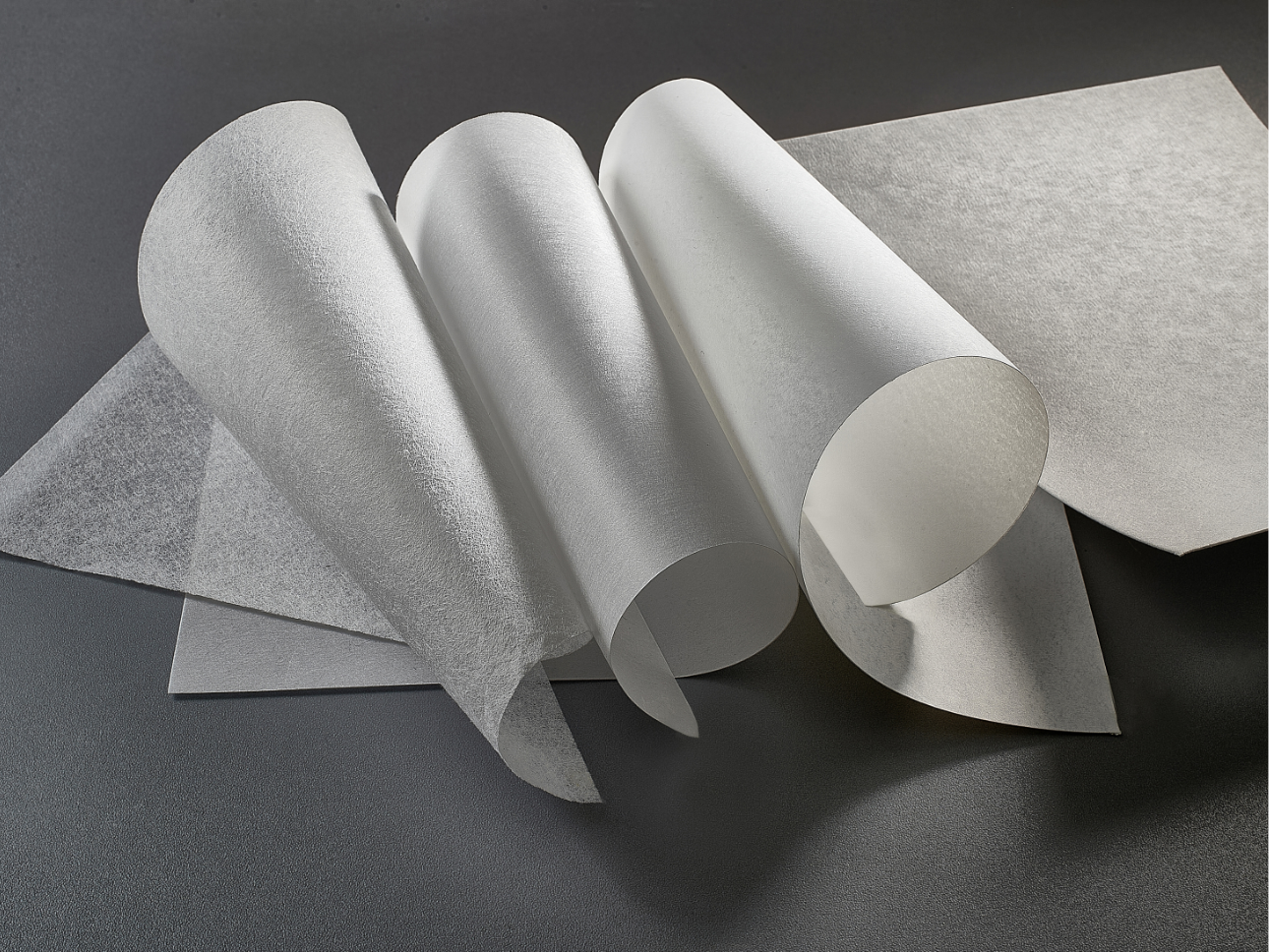

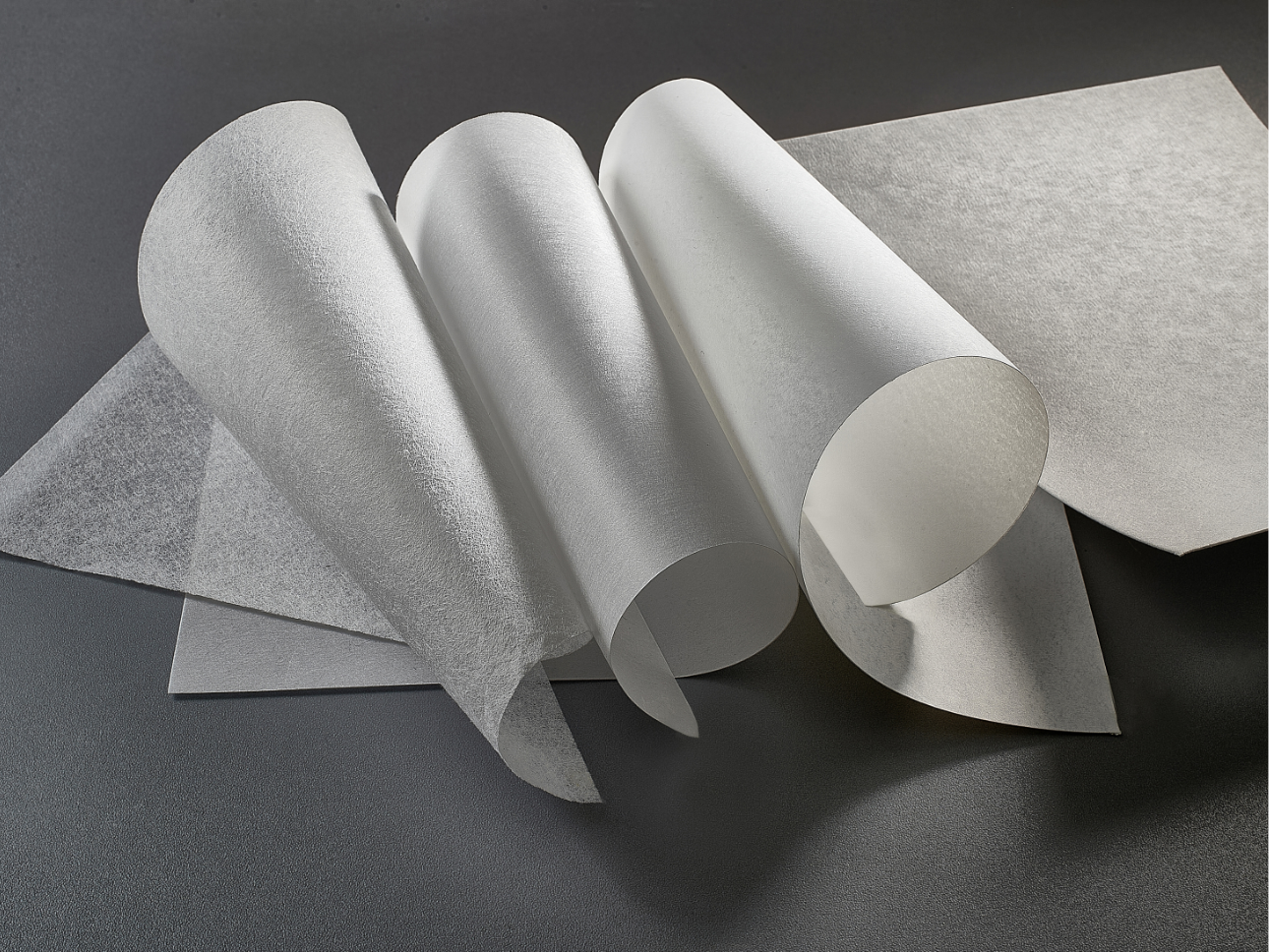

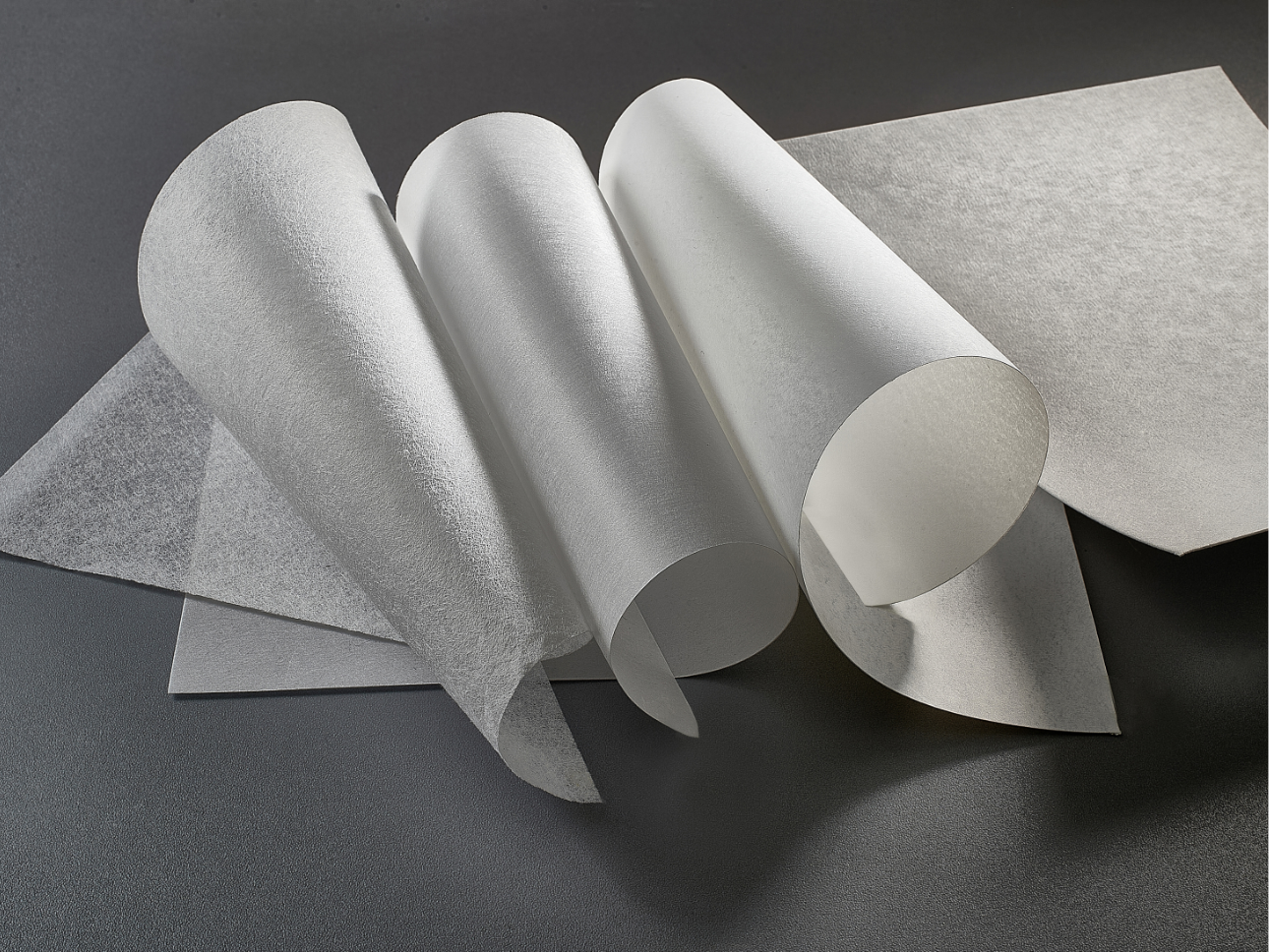

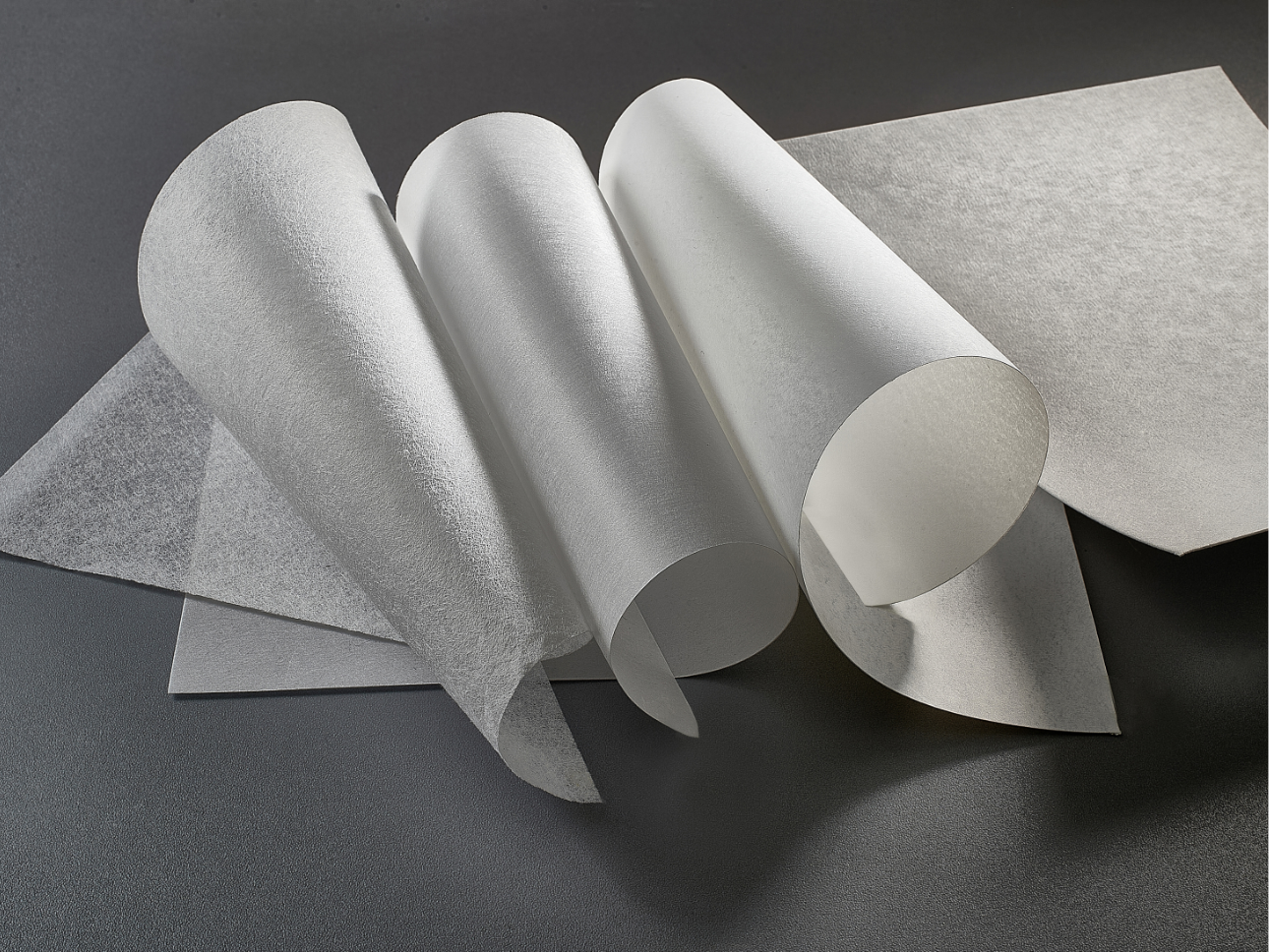

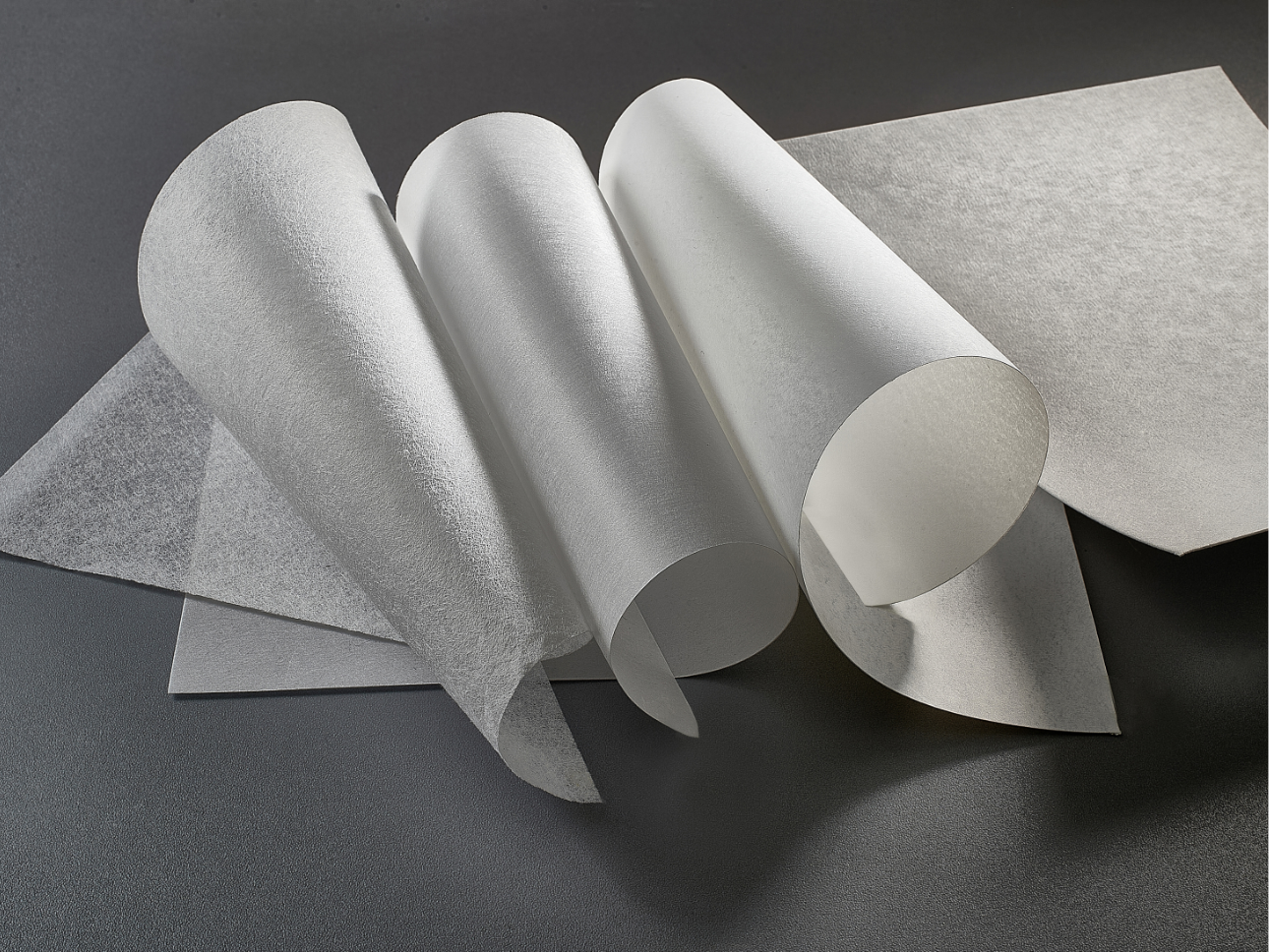

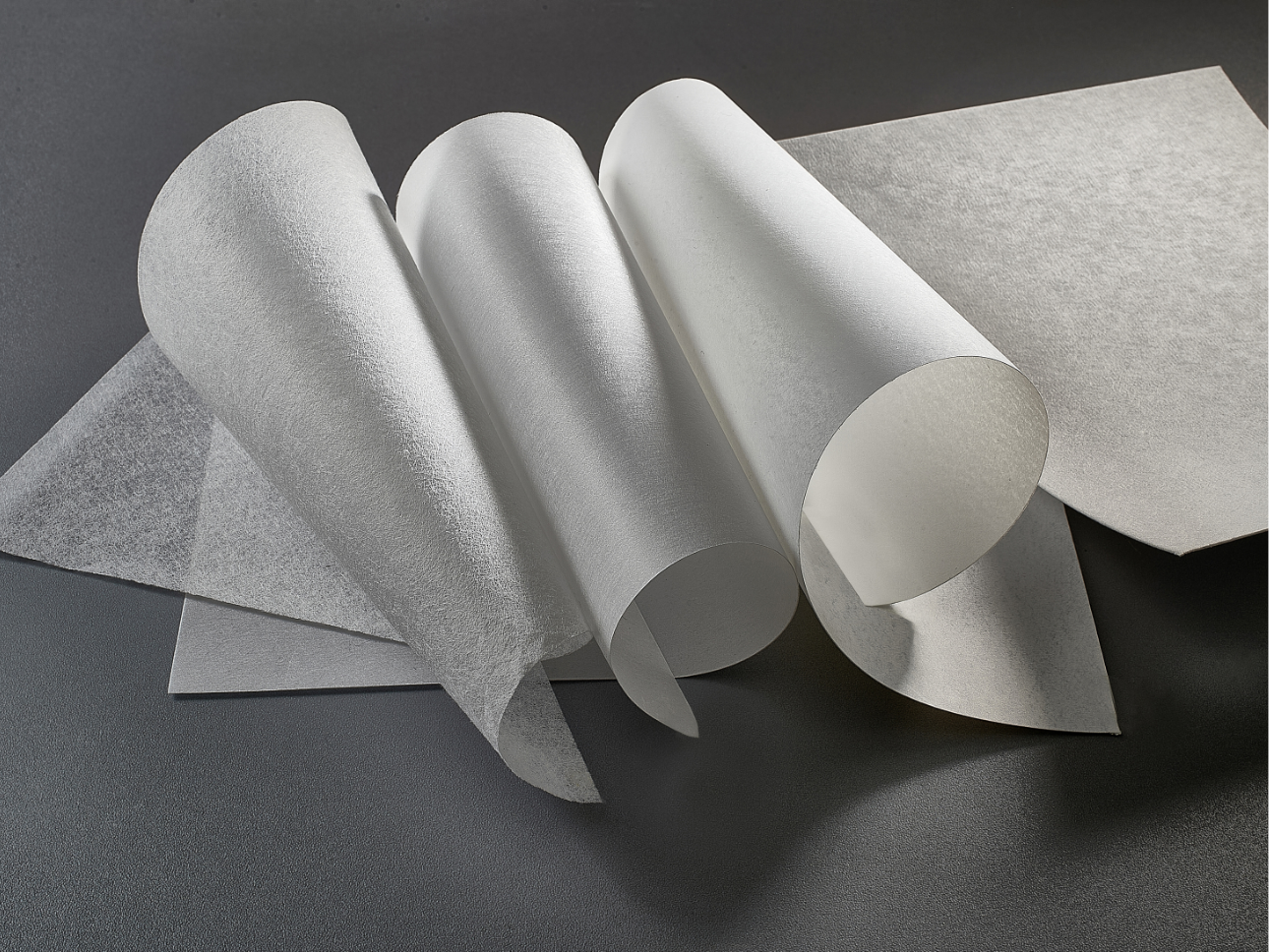

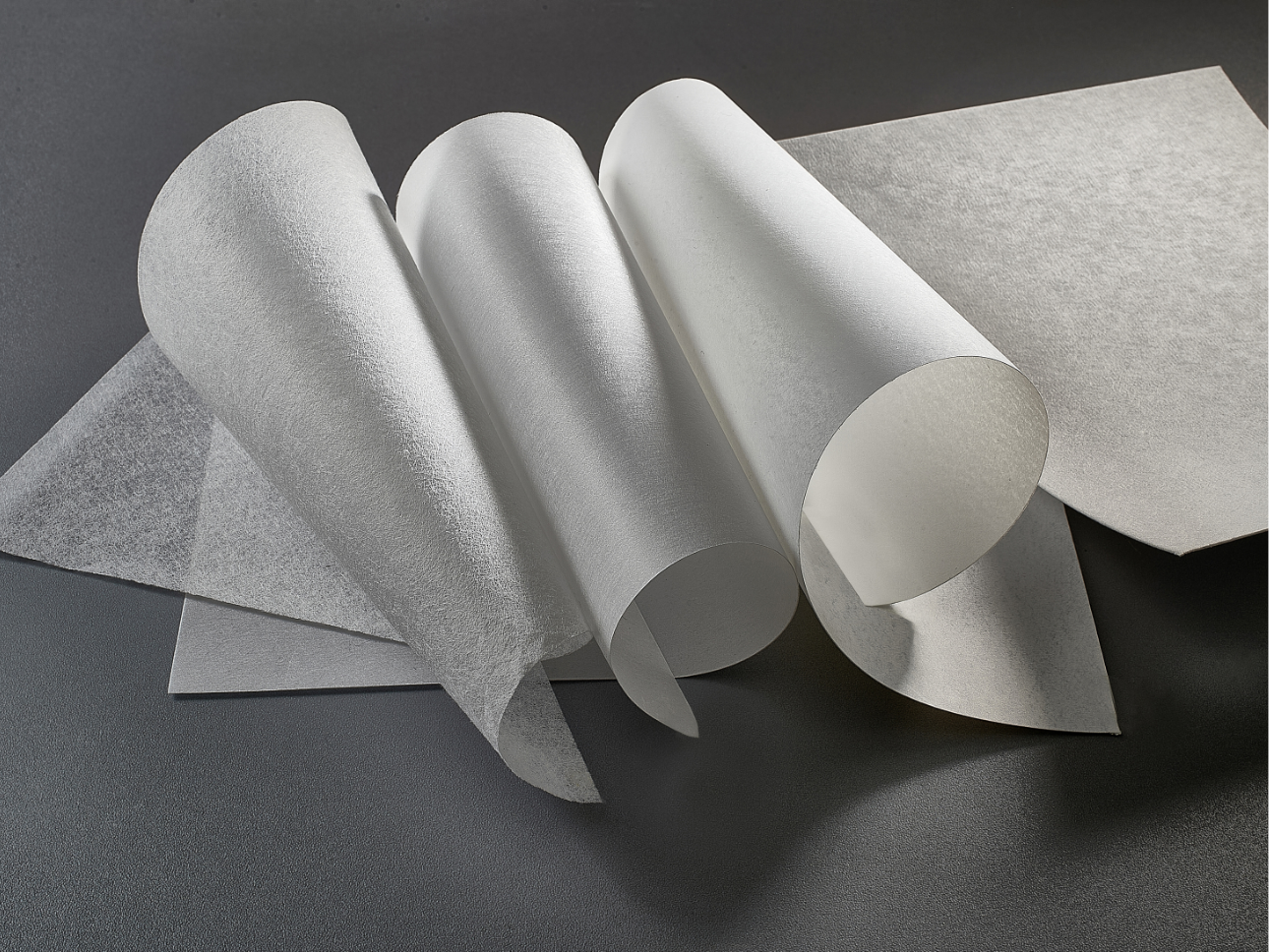

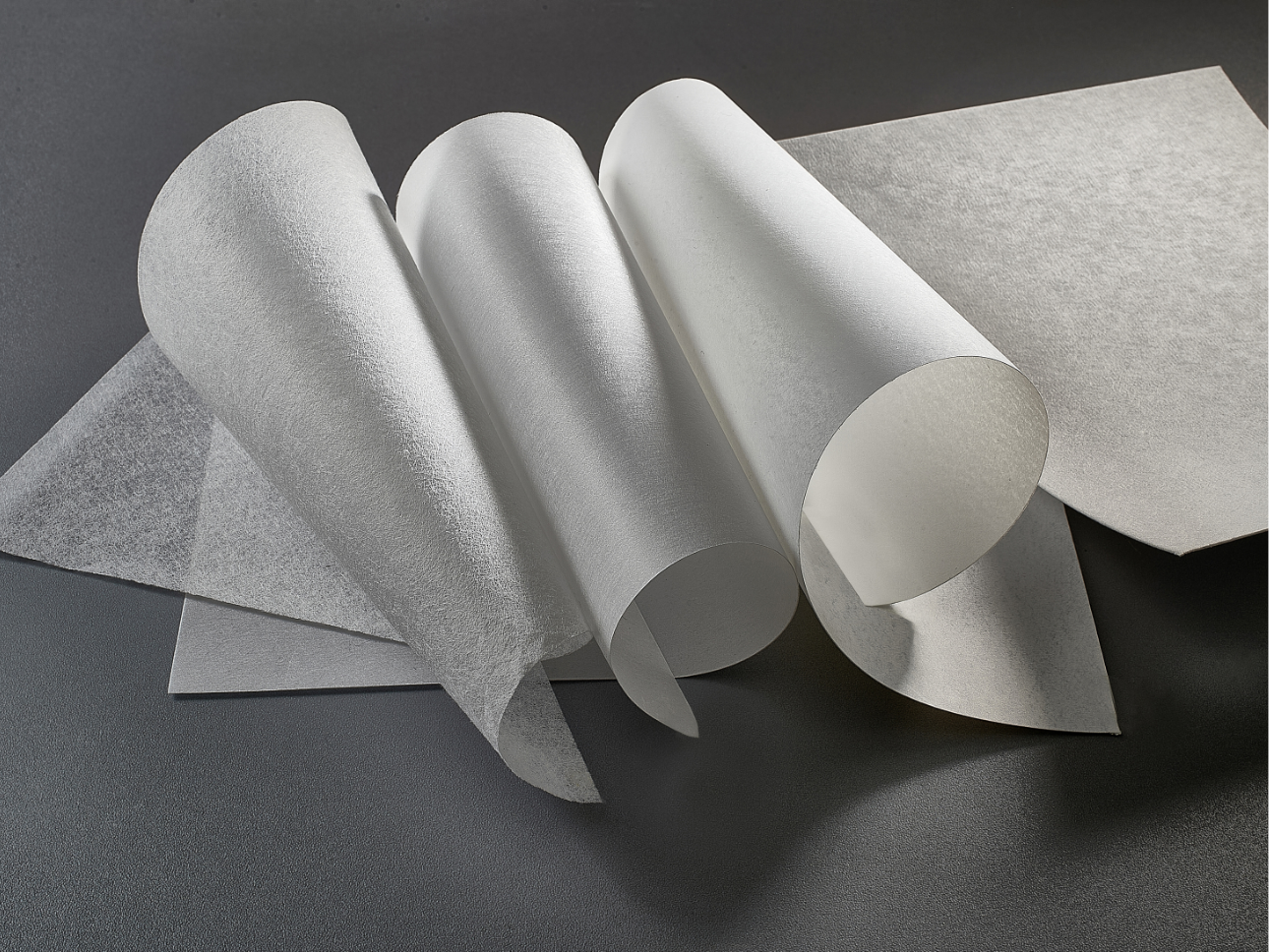

The Filtura® portfolio offers a wide range of state-of-the-art wetlaid nonwovens with superior web uniformity and high precision in weight, thickness and pore size. Using a variety of bonding processes and polymers, the fully synthetic fabrics can be tailored to different markets and applications for the most diverse filtration processes.

Applications

✓ Liquid filtration: e.g. food & beverage, water purification (reverse osmosis)

✓ Automotive filtration: e.g. transmission oil filtration

With years of production experience, our processes have been optimized to achieve reliable and stable results. The precise pore size and uniform fiber distribution ensure excellent reliability in filtration applications, as well as homogeneity and outstanding performance.

The Filtura® range of wetlaid nonwovens includes product variants with very fine fibers (under 2µm), making them ideal for manufacturing sophisticated filter materials. The resulting increased surface area and denser fiber network maximize the filtration capacity of the filter media.

Filtura® wetlaid nonwovens can be made from a variety of polymers, such as PES, PO, PA and PVA, as well as different types of fiber. Among other options, the addition of glass, viscose, and wood pulp is possible.

Our portfolio includes product options ranging from extremely lightweight, at less than 10 grams per square meter, to options weighing up to 300 grams per square meter. This diverse range allows us to cater to a wide array of applications, ensuring that we meet the specific needs of our clients across different industries.

With years of production experience, our processes have been optimized to achieve reliable and stable results. The precise pore size and uniform fiber distribution ensure excellent reliability in filtration applications, as well as homogeneity and outstanding performance.

The Filtura® range of wetlaid nonwovens includes product variants with very fine fibers (under 2µm), making them ideal for manufacturing sophisticated filter materials. The resulting increased surface area and denser fiber network maximize the filtration capacity of the filter media.

Filtura® wetlaid nonwovens can be made from a variety of polymers, such as PES, PO, PA and PVA, as well as different types of fiber. Among other options, the addition of glass, viscose, and wood pulp is possible.

Our portfolio includes product options ranging from extremely lightweight, at less than 10 grams per square meter, to options weighing up to 300 grams per square meter. This diverse range allows us to cater to a wide array of applications, ensuring that we meet the specific needs of our clients across different industries.

Learn more about the applications and solutions for liquid filtration powered by wetlaid and other technologies.

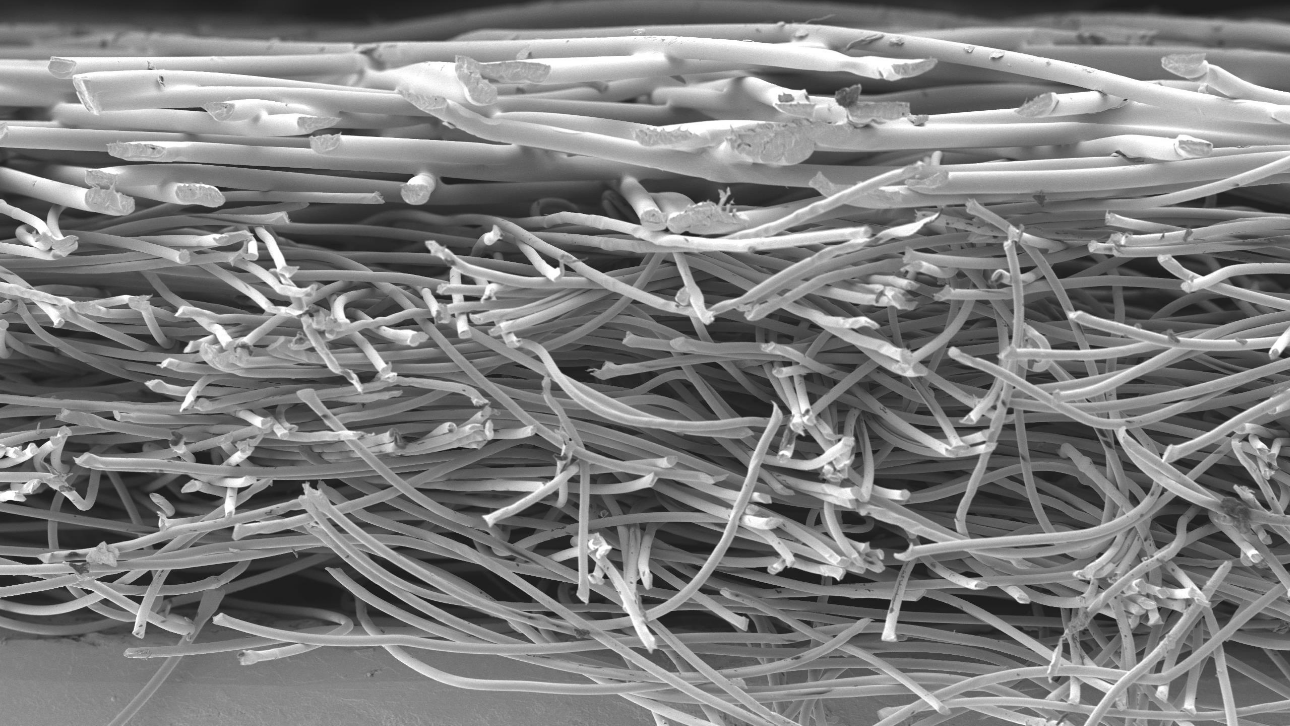

Filtura® high-quality 3D mats feature a unique monofilament structure of synthetic filaments that form a compression-resistant matrix. Approximately 95% of the geometry is open, allowing for efficient air and water flow. Filtura® 3D mats are an excellent habitat for the growth of microorganisms, making them perfect for bioscrubbers and biotrickling filters. These fabrics are also highly suitable as media in odor control units and water treatment systems.

Applications

✓ Air filtration: e.g. odor control/biotrickling

Filtura® 3D mats offer a broad range of “surface areas” as well as options for glueless bonding. The 3D mats can be manufactured in different weights, thicknesses (up to 22 mm) and colors, or shaped to different profiles. They can be compounded to achieve properties such as flame retardancy or UV stability.

The structure features a high surface area to volume ratio; the open flow channels support low pressure drop even at high air velocities. Filtura® 3D mats also have superior compression stability and uniformity.

Good news for filter manufacturers: Filtura® 3D mats are supplied on one meter wide rolls, are extremely lightweight and can be easily processed.

Filtura® 3D mats offer a broad range of “surface areas” as well as options for glueless bonding. The 3D mats can be manufactured in different weights, thicknesses (up to 22 mm) and colors, or shaped to different profiles. They can be compounded to achieve properties such as flame retardancy or UV stability.

The structure features a high surface area to volume ratio; the open flow channels support low pressure drop even at high air velocities. Filtura® 3D mats also have superior compression stability and uniformity.

Good news for filter manufacturers: Filtura® 3D mats are supplied on one meter wide rolls, are extremely lightweight and can be easily processed.

Reach out to our team for advise.

The Filtura® portfolio delivers high-performance nonwoven filter media for demanding applications in air, liquid, or automotive filtration. Our 100% synthetic solutions are a perfect alternative to glass fiber materials. Filtura® nonwovens excel in the most challenging environments to create tailored, market-driven solutions for filter manufacturers.

The Filtura® portfolio offers superior filter media, side bands, carrier materials and activated carbon solutions for the air filtration industry

Filtura®: 100% synthetic filter media, carrier materials and reverse osmosis solutions for the liquid filtration industry

Filtura®: 100% synthetic filter media, side bands, carrier materials and activated carbon solutions for the automotive filtration industry

Discover solutions powered by the broad range of technological capabilities at Filtura

Filtura® Support range offers perfect carrier material for filtration applications including carbon activated filter media

The Filtura® Media range includes efficient filter media perfect for manufacturing automotive, liquid, and air filtration systems.

The Filtura® Edge range offers high-quality side bands perfect for automotive, liquid, and air filtration.

With Filtura® Carbon, we offer solutions with variable activated carbon content that optimizes air filtration applications.